Split Spherical Roller Bearings

|

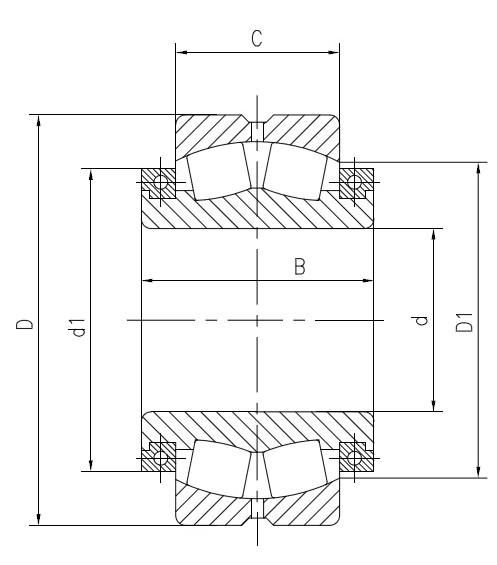

Designation |

Boundary Dimension(mm) |

Basic load ratings |

Mass |

||||||||

|

Code |

d |

D |

B |

C |

rsmin |

r1smin |

d1 |

D1 |

Cr(KN) |

Cor(KN) |

(Kg) |

| 803824 | 120 | 200 | 142 | 80 | 2 | 2 | 166 | 169 | 555 | 900 | 17 |

| 803928 | 140 | 230 | 102 | 53 | 2 | 2 | 180 | 190 | 600 | 190 | 14 |

| 803828 | 140 | 290 | 110 | 80 | 3 | 3 | 193 | 247.5 | 838 | 1145 | 31.2 |

| 803830X3 | 148 | 225 | 142 | 75 | 2.1 | 2.1 | 180 | 197 | 535 | 950 | 14 |

| 803836 | 180 | 300 | 125 | 74 | 2.1 | 2.1 | 220 | 248 | 715 | 1200 | 30 |

| 803856 | 280 | 500 | 260 | 176 | 5 | 5 | 419 | 439 | 2710 | 4650 | 175 |

| 803860 | 300 | 500 | 240 | 160 | 5 | 5 | 418 | 434 | 2527 | 4465 | 165 |

| 803864K | 320 | 540 | 250 | 176 | 6 | 6 | 439 | 454 | 2395 | 4586 | 196.5 |

| 803868 | 340 | 580 | 280 | 190 | 5 | 5 | 475 | 487 | 2930 | 5574 | 235 |

| 803872 | 360 | 540 | 220 | 134 | 5 | 5 | 476 | 482 | 2250 | 4500 | 155 |

| 803880 | 400 | 600 | 240 | 148 | 5 | 5 | 522 | 541 | 2880 | 5850 | 205 |

| 803884 | 420 | 620 | 238 | 150 | 6 | 6 | 542 | 562 | 2880 | 5850 | 215 |

| 803892 | 460 | 700 | 245 | 165 | 6 | 6 | 604 | 635 | 3280 | 6550 | 340 |

| 803894 | 470 | 720 | 270 | 167 | 6 | 6 | 646 | 656 | 3570 | 7500 | 375 |

| 8039/560 | 560 | 800 | 230 | 150 | 5 | 5 | 669 | 742 | 3340 | 8150 | 320 |

| 8038/560 | 560 | 870 | 330 | 200 | 6 | 6 | 733 | 786 | 5060 | 11000 | 580 |

| 8039/600 | 600 | 920 | 310 | 212 | 9.5 | 7.5 | 798 | 837 | 5640 | 12000 | 690 |

| 8038/600 | 600 | 980 | 515 | 375 | 7.5 | 7.5 | 811 | 833 | 10400 | 21600 | 1350 |

| 8038/630 | 630 | 920 | 310 | 212 | 16 | 7.5 | 800 | 825 | 5245 | 11390 | 628 |

| 8038/670 | 670 | 980 | 350 | 230 | 7.5 | 7.5 | 860 | 890 | 6440 | 14000 | 800 |

| 8039/710 | 710 | 950 | 375 | 243 | 6 | 6 | 860 | 868 | 5750 | 15300 | 700 |

| 8038/710 | 710 | 1030 | 360 | 236 | 7.5 | 7.5 | 901 | 939 | 7020 | 15600 | 880 |

| 8039/750 | 750 | 1000 | 360 | 250 | 6 | 6 | 900 | 916 | 6300 | 17000 | 710 |

| 8038/750 | 750 | 1090 | 340 | 250 | 8 | 8 | 950 | 980 | 6600 | 15330 | 932 |

| 8038/750X2 | 750 | 1090 | 475 | 335 | 7.5 | 7.5 | 938 | 969 | 9950 | 24000 | 1300 |

| 8039/800 | 800 | 1060 | 370 | 258 | 6 | 6 | 955 | 968 | 6900 | 18600 | 8100 |

| 8038/800 | 800 | 1150 | 450 | 345 | 16 | 8 | 1010 | 1018 | 10000 | 24800 | 1500 |

| 8037/850 | 850 | 1120 | 380 | 272 | 6 | 6 | 1008 | 1028 | 7360 | 2800 | 830 |

| 8039/850 | 850 | 1180 | 331 | 206 | 6 | 6 | 1070 | 1100 | 6440 | 17000 | 880 |

| 8038/850 | 850 | 1280 | 430 | 280 | 7.5 | 7.5 | 1120 | 1177 | 10100 | 23200 | 1550 |

| 8038/850X1 | 850 | 1280 | 540 | 375 | 7.5 | 7.5 | 1123 | 1147 | 12400 | 31000 | 2350 |

| 8039/900 | 900 | 1180 | 400 | 280 | 6 | 6 | 1058 | 1086 | 8170 | 22800 | 1100 |

| 8038/900 | 900 | 1270 | 470 | 365 | 15 | 15 | 1160 | 1137 | 10000 | 28000 | 1872 |

| 8038/950 | 950 | 1250 | 420 | 300 | 7.5 | 7.536 | 1130 | 1150 | 8970 | 25500 | 1300 |

| 8038/1020 | 1020 | 1280 | 352 | 218 | 6 | 6 | 1192 | 1210 | 5980 | 19600 | 950 |

| 8038/1060 | 1060 | 1460 | 500 | 335 | 7.5 | 7.5 | 1330 | 1350 | 11500 | 33500 | 2470 |

| 8039/1120 | 1120 | 1460 | 500 | 335 | 7.5 | 7.5 | 1330 | 1350 | 11500 | 33500 | 2070 |

| 8038/1120 | 1120 | 1540 | 525 | 355 | 7.5 | 7.5 | 1401 | 1420 | 14400 | 44000 | 2850 |

| 8038/1250 | 1250 | 1750 | 560 | 375 | 9.5 | 9.5 | 1560 | 1607 | 19600 | 50000 | 3800 |

Split spherical roller bearings

LYNBC provide split to the shaft roller bearings with a range of additions, which can be tailored to suit your specific application. And, if we don’t already make it, then we can work with you to produce a bespoke split roller bearing to solve your particular problem. LYNBC is always striving for continuous innovation, spurred by competition and the desire to provide you and your customers with constant productivity improvements and high value. Such below

Split spherical roller bearings are primarily used for bearing positions which are difficult to access such as on long shafts which require support at several positions, or on cranked shafts. Their use is also beneficial where non-split bearings would require considerable time and effort for maintenance and more particularly for replacement; this would also cause long and expensive, or perhaps even inadmissibly long machine downtime. Split spherical roller bearings offer the optimum solution to such problems. The main application areas include conveyor equipment, long multiple-supported shafts and large ventilation plants .

LYNBC split spherical roller bearings/single row cylindrical roller bearings are produced to order. The design is tailored to the particular application and, for cost reasons, is generally based on available bearings of standard design. The selection of bearings shown in the tables is intended to illustrate the LYNBC manufacturing capability; these bearings have been made. Before finalising a bearing arrangement design incorporating a split roller bearings, it is advisable to consult the LYNBC application engineering service.

▲ The design’s of all these Split Roller Bearings are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

If you have any suggestions or opinions about our products,please leave a message,and we will immediately answer your questions. Thanks for your support.

Previous Article:Split Cylindrical Roller Bearings

Next Article:Deep groove ball bearings

.jpg)