|

Designation |

Boundary Dimension |

Mounting Hole Size |

Gear Data |

Basic load ratings |

Mass |

|||||||||||||

|

No Gear |

External Gear |

Internal Gear |

D |

d |

H |

D1 |

D2 |

n |

Φ |

m |

Da |

Z |

da |

Z |

b |

x |

Coa (10KN) |

(Kg) |

| 020.25.500 | 021.25.500 | 023.25.500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 5 | 645 | 126 | 355 | 72 | 60 | 0.5 | 121 | 100 |

| 022.25.500 | 024.25.500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 6 | 648 | 105 | 348 | 59 | 60 | 0.5 | 121 | 100 | |

| 020.25.560 | 021.25.560 | 023.25.560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 5 | 705 | 138 | 415 | 84 | 60 | 0.5 | 134 | 115 |

| 022.25.560 | 024.25.560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 6 | 708 | 115 | 408 | 69 | 60 | 0.5 | 134 | 115 | |

| 020.25.630 | 021.25.630 | 023.25.630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 6 | 792 | 129 | 480 | 81 | 60 | 0.5 | 153 | 130 |

| 022.25.630 | 024.25.630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 8 | 792 | 96 | 472 | 60 | 60 | 0.5 | 153 | 130 | |

| 020.25.710 | 021.25.710 | 023.25.710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 6 | 864 | 141 | 558 | 94 | 60 | 0.5 | 173 | 140 |

| 022.25.710 | 024.25.710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 8 | 864 | 105 | 552 | 70 | 60 | 0.5 | 173 | 140 | |

| 020.30.800 | 021.30.800 | 023.30.800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 8 | 984 | 120 | 616 | 78 | 80 | 0.5 | 230 | 200 |

| 022.30.800 | 024.30.800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 10 | 990 | 96 | 610 | 62 | 80 | 0.5 | 230 | 200 | |

| 020.30.900 | 021.30.900 | 023.30.900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 8 | 1088 | 133 | 712 | 90 | 80 | 0.5 | 258 | 250 |

| 022.30.900 | 024.30.900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 10 | 1090 | 106 | 710 | 72 | 80 | 0.5 | 258 | 250 | |

| 020.30.1000 | 021.30.1000 | 023.30.1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 10 | 1200 | 117 | 810 | 82 | 80 | 0.5 | 286 | 300 |

| 022.30.1000 | 024.30.1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 12 | 1200 | 97 | 792 | 67 | 80 | 0.5 | 286 | 300 | |

| 020.30.1120 | 021.30.1120 | 023.30.1120 | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 10 | 1320 | 129 | 920 | 93 | 80 | 0.5 | 321 | 340 |

| 022.30.1120 | 024.30.1120 | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 12 | 1320 | 107 | 912 | 77 | 80 | 0.5 | 321 | 340 | |

| 020.40.1250 | 021.40.1250 | 023.40.1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 12 | 1500 | 122 | 1008 | 85 | 90 | 0.5 | 482 | 580 |

| 022.40.1250 | 024.40.1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 14 | 1498 | 104 | 1008 | 73 | 90 | 0.5 | 482 | 580 | |

| 020.40.1400 | 021.40.1400 | 023.40.1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 12 | 1644 | 134 | 1152 | 97 | 90 | 0.5 | 543 | 650 |

| 022.40.1400 | 024.40.1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 14 | 1652 | 115 | 1148 | 83 | 90 | 0.5 | 543 | 650 | |

| 020.40.1600 | 021.40.1600 | 023.40.1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 14 | 1848 | 129 | 1344 | 97 | 90 | 0.5 | 620 | 750 |

| 022.40.1600 | 024.40.1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 16 | 1856 | 113 | 1344 | 85 | 90 | 0.5 | 620 | 750 | |

| 020.40.1800 | 021.40.1800 | 023.40.1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 14 | 2058 | 144 | 1540 | 111 | 90 | 0.5 | 692 | 820 |

| 022.40.1800 | 024.40.1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 16 | 2064 | 126 | 1536 | 97 | 90 | 0.5 | 692 | 820 | |

| 020.50.2000 | 021.50.2000 | 023.50.2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 16 | 2304 | 141 | 1696 | 107 | 120 | 0.5 | 987 | 1150 |

| 022.50.2000 | 024.50.2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 18 | 2304 | 125 | 1692 | 95 | 120 | 0.5 | 987 | 1150 | |

| 020.50.2240 | 021.50.2240 | 023.50.2240 | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 16 | 2544 | 156 | 1936 | 122 | 120 | 0.5 | 1110 | 1500 |

| 022.50.2240 | 024.50.2240 | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 18 | 2556 | 139 | 1926 | 108 | 120 | 0.5 | 1110 | 1500 | |

| 020.50.2500 | 021.50.2500 | 023.50.2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 18 | 2804 | 153 | 2196 | 123 | 120 | 0.5 | 1110 | 1500 |

| 022.50.2500 | 024.50.2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 20 | 2820 | 138 | 2180 | 110 | 120 | 0.5 | 1110 | 1500 | |

| 020.50.2800 | 021.50.2800 | 023.50.2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 18 | 3114 | 170 | 2484 | 139 | 120 | 0.5 | 1390 | 1900 |

| 022.50.2800 | 024.50.2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 20 | 3120 | 153 | 2480 | 125 | 120 | 0.5 | 1390 | 1900 | |

| 020.60.3150 | 020.60.3150 | 020.60.3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 20 | 3540 | 174 | 2760 | 139 | 150 | 0.5 | 1870 | 3300 |

| 020.60.3150 | 020.60.3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 22 | 3542 | 158 | 2750 | 126 | 150 | 0.5 | 1870 | 3300 | |

| 020.60.3550 | 021.60.3550 | 023.60.3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 20 | 3940 | 194 | 3160 | 159 | 150 | 0.5 | 2110 | 3700 |

| 022.60.3550 | 024.60.3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 22 | 3938 | 176 | 3168 | 145 | 150 | 0.5 | 2110 | 3700 | |

| 020.60.4000 | 021.60.4000 | 023.60.4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 22 | 4400 | 197 | 3608 | 165 | 150 | 0.5 | 2370 | 4200 |

| 022.60.4000 | 024.60.4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 25 | 4400 | 173 | 3600 | 145 | 150 | 0.5 | 2370 | 4200 | |

| 020.60.4500 | 021.60.4500 | 023.60.4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 22 | 4884 | 219 | 4114 | 188 | 150 | 0.5 | 2670 | 4700 |

| 022.60.4500 | 024.60.4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 25 | 4900 | 193 | 4100 | 165 | 150 | 0.5 | 2670 | 4700 | |

Double-row Ball Slewing bearing

LYNBC double-row ball slewing bearing can carry axial loads, tilting moment and radial loads at the same time. The top balls mainly carry the axial load and positive tilting moment. The drop balls take the opposite tilting moment. This is the reason why the loading capacity of the double row ball slewing bearing is larger than the four-point contact ball slewing bearing; However, the frictional ratio is larger than the latter.

LYNBC double-row ball slewing bearing consists of inner ring, outer ring, balls in double rows, spacers, sealing device, etc. Because the top balls mainly take the axial load and tilting moment, the size of top balls are larger than the drop balls. In order to accommodate the various working condition at different axial load, tilting moments and axial load, the angle of contact would be adjusted accordingly.

The rings structure can be divided into two types, integral type and split type. Generally, the integral type maintains a stronger rigidity. The split type is more convenient to adjust; the two segregate rings are fastened by bolts before delivery.

LYNBC double-row slewing bearing has cages(or spacers) among the balls. Only when large loading is requested, would the full ball type be applied. Loading capacity for full ball type is definitely larger, However, the increased friction generated by this design allows for the balls to be easily scratched.

The double-row slewing bearing is mainly for the working conditions when carrying axial load, larger tilting moment, and where the mounting place is limited in radial direction. This structure has smallest sensitive in mounting precision and deformation in axial and radial direction.

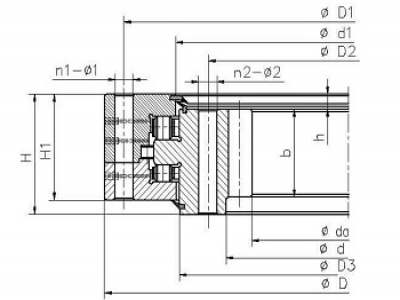

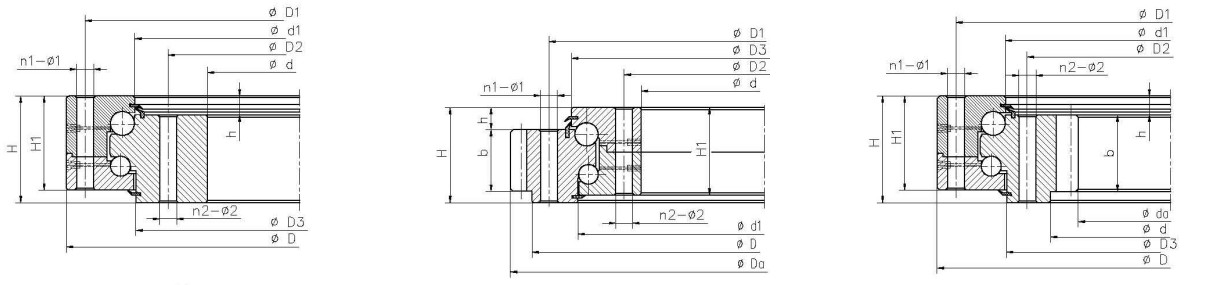

The basic structures of LYNBC double-row ball slewing bearing as below:

Without gear

External gear

Internal gear

▲ The design’s of all these slewing bearing are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

.jpg)