.jpg)

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Products list

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Contact Us

- Luoyang Nice Bearing Co.,Ltd.

- Address:Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- E-mail:sales@lynicebearing.com

- E-mail:techsupport@lynicebearing.com

- Tel:+86-0379-60689957

- Fax:+86-0379-60689929

- skype:Nettie.Ma

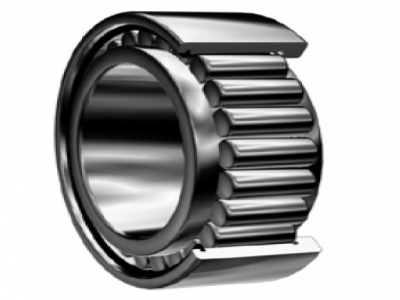

Full Complement Cylindrical Roller Bearings

Full Complement Cylindrical Roller Bearings

Roller bearings can carry heavy load. Compared to traditional bearings with case, our full complement cylindrical roller bearings have higher loading capacity. Based on the same width, the roller bearings have smaller radial cross section, so they are space-saving but their rotary speed is lower relatively. All the multi-stage cylindrical roller bearings are designed with a lubrication groove and a lubricating hole on the outer ring.

As a professional roller bearing manufacturer and supplier in China, we mainly provide such below products for our clients.

1. Single Row Full Complement Cylindrical Roller Bearings;

2. Double Row Full Complement Cylindrical Roller Bearings;

3. Three Row Full Complement Cylindrical Roller Bearings;

4. Both Directions Positioning Double Row Full Complement Cylindrical Roller Bearings;

5. Double Row Full Complement Cylindrical Roller Bearings With Snap groove on the outer ring and double seals;

6. Double Row Full Complement Cylindrical Roller Bearings (Floating Type);

7. Spherical Double Row Full Complement Cylindrical Roller Bearings (Floating Type);

8. Spherical Double Row Full Complement Cylindrical Roller Bearings (Positioning Type);

9. Single Row Full Complement Cylindrical Roller Bearings with disc cage;

These roller bearings have the advantages of high loading capacity, high accuracy, easy installation and long service life, and so on.

They are widely used in motors, locomotives and rolling stocks, machine tool spindles, internal combustion engines, generators, gas turbines, vibrating screens, hoisting machines, and conveying machinery, etc.

Roller bearings must support a certain minimum load(namely, C/P<25)to ensure the normal operation in succession. If not, wear would be exacerbated when the lubrication is not enough or the running speed is high.

▲ The design’s of all these Full Complement Cylindrical Roller Bearings series are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

Contact Us

Luoyang Nice Bearing Co.,Ltd.

- Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- sales@lynicebearing.com

- techsupport@lynicebearing.com

- +86-0379-60689957

- +86-0379-60689929

- Nettie.Ma

Leave a Message

Please leave a message,and we will immediately answer your questions.

Copyright © 2015 Luoyang Nice Bearing Co.,Ltd. All rights Reserved. Privacy Policy Powered by MetInfo