.jpg)

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Products list

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Contact Us

- Luoyang Nice Bearing Co.,Ltd.

- Address:Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- E-mail:sales@lynicebearing.com

- E-mail:techsupport@lynicebearing.com

- Tel:+86-0379-60689957

- Fax:+86-0379-60689929

- skype:Nettie.Ma

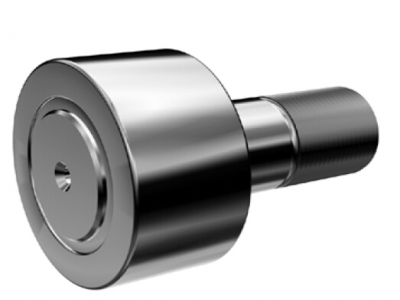

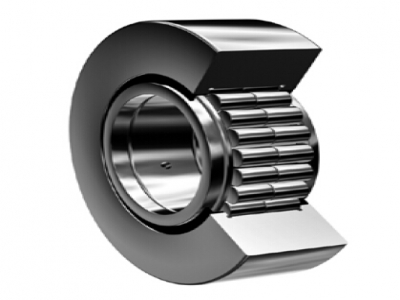

Track Roller Bearings

Track Rollers

Stud type track rollers are similar in their construction to single and double row yoke type track rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread and lubrication hole. Due to the thick-walled outer ring with profiled outside surface and the rolling element set, they can support high radial loads as well as axial loads arising from slight misalignment and skewed running; they are suitable for applications such as cam gears, bed ways and conveying equipment.

Due to a modified material and the optimized raceway geometry of the outer rings for Yoke type track rollers or Stud type track rollers, the basic rating life has been increased by up to 30%.The static and dynamic load carrying capacity has also been increased. At the same time, the stress placed on the mating track has been reduced as a result of the optimised lateral surface profile and its improved surface quality. Due to these measures, highly robust bearing arrangements with an extended operating life can be achieved.

▲ The design’s of all these Stud Type Track Rollers are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

Contact Us

Luoyang Nice Bearing Co.,Ltd.

- Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- sales@lynicebearing.com

- techsupport@lynicebearing.com

- +86-0379-60689957

- +86-0379-60689929

- Nettie.Ma

Leave a Message

Please leave a message,and we will immediately answer your questions.

Copyright © 2015 Luoyang Nice Bearing Co.,Ltd. All rights Reserved. Privacy Policy Powered by MetInfo